GRAVITY GOODS ROPEWAY

During the movement, the trolley moves back and

forth in the track rope so the minimal impact load

is imparted to the track rope. It is considered to

be 10 per cent of the total impact load.

As the impact is the change in momentum per

unit time, sudden application of brake should be

avoided to minimise the impact. For this, a braking

distance can be calculated and the operator

should be oriented on this to start application of

brake when the trolley reaches to the start of the

breaking distance so that uniform retardation is

achieved.

Maximum possible loads: Maximum possible load

in track rope = wt. of track rope + wt. of trolley +

wt. of downward moving goods + 50 per cent of

weight of haulage rope + 1/3rd of maximum wind

load + 10 percent of impact load

Maximum load in haulage rope = wt. of the

haulage rope + maximum wind load + 50 percent

of impact load.

The rope factor of safety should be checked for

the following two loading conditions:

Dead load + maximum wind load

Full load + 1/3rd of maximum wind load

+ impact load

As the gravity ropeways operate in the hilly

terrains, consideration of wind load is very crucial.

The operation of the ropeway during heavy storms

should be strictly prohibited.

3.1.5 Rope tension calculation

For rope tension calculation, first of all the rope

sag at dead load is assumed and the rope tension

is calculated for the corresponding sag. The full

load sag is then obtained from iterative methods

but more conveniently from computer analysis

like SAP.

Tension in the wire rope is calculated from the

following relation.

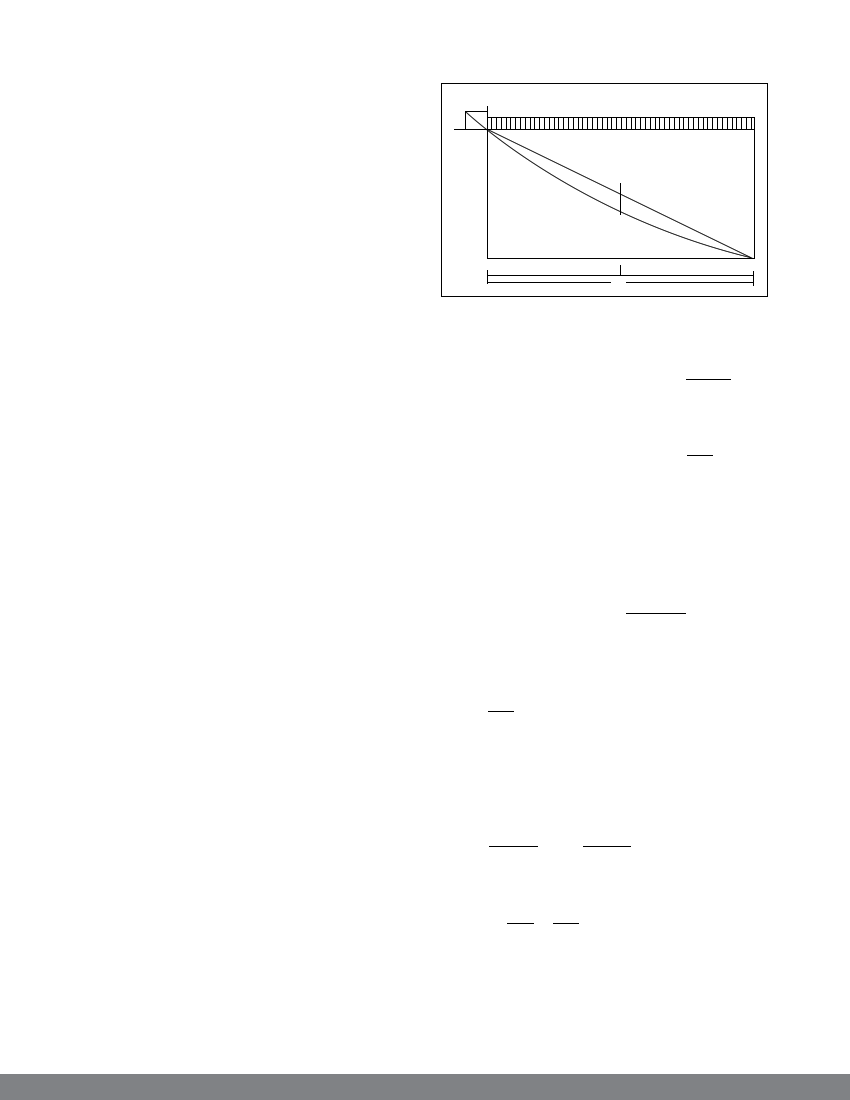

T

H β1

w

w

bx

x

I

I-x

Figure 16

For uniformly distributed load (w)

Horizontal reaction at point x (Hx) = wx(l-x)

2bx

Hx is maximum when bx = b

Maximum horizontal reaction (H ) = wl2

8b

where w is weight per metre and b is the maximum

sag.

For point load (w)

When the point load is at x,

Horizontal reaction (Hx) = Wx (l -x)

bx

The reaction is maximum when the point load is

at the centre. Hence,

Hmax = WL

4b

where W is point load and b is the maximum

sag.

Point and live load in combination

At x,

Hx = wx(l-x) + Wx(l -x)

2bx bx

When bx = b,

Hmax = wl2 + Wl

8b 4b

20